Compactness

When the thickness is about 3mm, its permeability is &×10ˉ11m/sec, which is equivalent to 100 times the compactness of 30cm thick clay, and has strong self-retaining properties.

It has permanent waterproof properties

Because sodium bentonite is a natural inorganic material, it will not deteriorate or corrode even after a long period of time or changes in the surrounding environment, so it has long-lasting waterproof properties.

The construction is simple and the construction period is short

Compared with other waterproof materials, the construction is relatively simple, and does not require heating and pasting. Just connect and fix with bentonite powder and nails, gaskets, etc. No special inspection is required after construction, and it is easy to repair if waterproof defects are found. GCL has the shortest construction period among the existing waterproofing materials.

Unaffected by temperature

It does not break in cold climates.

integration

Integration of waterproof material and object: when sodium-based bentonite encounters water, it has 20-28 times the expansion capacity, even if the concrete structure vibrates and settles, the bentonite in GCL can repair the cracks on the concrete surface within 2mm.

Environmentally friendly

Bentonite is a natural inorganic material, which is harmless and non-toxic to the human body, has no special impact on the environment, and has good environmental performance.

Features:

The performance-to-price ratio is high, and it is very versatile. The product range can reach 6 meters, which greatly improves the construction efficiency.

Scope of application and application conditions: suitable for municipal (landfill), water conservancy, environmental protection, artificial lakes and building underground waterproofing and anti-seepage projects.

It can still be constructed under the negative temperature (-20 °C) that can not be constructed by traditional waterproof materials, can also be constructed on wet base (no open water), can not be constructed in rainy and snowy weather, is not suitable for strong acid, strong alkaline solution seepage, and because bentonite is an inorganic material, its durability is better than that of organic waterproof materials.

Construction precautions for geosynthetic clay liner (GCL)

1. The storage and transportation of bentonite composite waterproof mat (GCL) should be waterproof, moisture-proof, and resistant to strong sunlight exposure. When storing, the ground should be elevated and the bentonite composite waterproof mat (GCL) transported to the site should be used up on the same day.

2. When carrying out the next process or adjacent engineering construction, the completed bentonite composite waterproof mat (GCL) should be properly protected and not damaged by any human factors.

3. Try to avoid wearing spiked shoes or high heels on the bentonite composite waterproof mat (GCL) as much as possible; Vehicles and other machinery are not allowed to crush the bentonite composite waterproof mat (GCL).

4. In the construction of GM/GCL composite lining, the completed GCL should be constructed with HDPE film or a 300mm thick clay protective layer on the same day. If the construction of HDPE film or clay protective layer cannot be completed on the same day, the GCL should be covered to prevent it from being hydrated and exposed to strong sunlight due to rain and snow.

5. After the anti-seepage and waterproofing construction of GCL single-layer liner is completed and accepted, it should be quickly backfilled with soil, sand or stone particles with a specific gravity greater than 2.0. To prevent damage to GCL during backfilling, the backfill soil should not contain crushed stones with a particle size greater than 10mm, and the thickness of the backfill soil should not be less than 30cm. Backfill soil should be graded and compacted, with a compaction degree not less than 85%.

Construction site protection of geosynthetic clay liner (GCL)

1. After the installation of the bentonite waterproof blanket, the geotextile membrane should be laid in a timely manner to avoid being eroded by wind and rain.

2. If the geotextile cannot be laid in a timely manner after the installation of the bentonite waterproof blanket, it should be covered with colored cloth or film to avoid being corroded by wind and rain; 3. After the installation of the bentonite waterproof blanket, it should be avoided from vehicle rolling and other foreign object damage.

4. After the construction is completed, there should be no mud, dirt, debris or other foreign objects on the bentonite cushion that may damage the anti-seepage layer.

Storage and transportation: a. Bentonite waterproof blanket (GCL) rolls should be protected from damage before installation and unfolding. Bentonite waterproof blanket (GCL) rolls should be stacked in a flat and waterlogged area, with a height not exceeding four rolls, and the roll identification plate should be visible.

5. Damage to the bentonite waterproof blanket (GCL) caused by improper storage and operation is not allowed to be used in this project.

6. During transportation (including on-site transportation from material storage to work), the bentonite waterproof blanket (GCL) roll should be protected from damage.

7. The bentonite waterproof blanket (GCL) roll that has been physically damaged must be repaired, and the severely damaged bentonite pad (GCL) cannot be used. We will remove it from the site and replace it.

8. Any bentonite (GCL) material that comes into contact with leaked chemical solvents is not allowed to be used in this project according to the judgment of the supervising engineer.

9. If the bentonite blanket is damaged (torn, punctured, etc.) during installation, a patch can be cut from a new roll of bentonite blanket to cover the damaged area for repair. The distance between the four sides of the patch and the damaged area should not be less than 300mm. Before laying the patch, some granular bentonite or bentonite slurry should be sprinkled around the damaged area. If necessary, some adhesive can also be used to prevent the "patch" from shifting, or a small piece of bentonite blanket can be placed under the damaged area.

Commercially available geoclay liner product specifications are differentiated by length, width, or mass per unit area of bentonite blanket. According to the width of 1m to 6m, the length varies from 20m to 60m, and it can also be produced according to the design requirements; According to the quality of the unit area of bentonite waterproof blanket, it is generally divided into several specifications such as 4000g/㎡, 4500g/㎡, 5000g/㎡, 5500g/㎡, and 6000g/㎡.

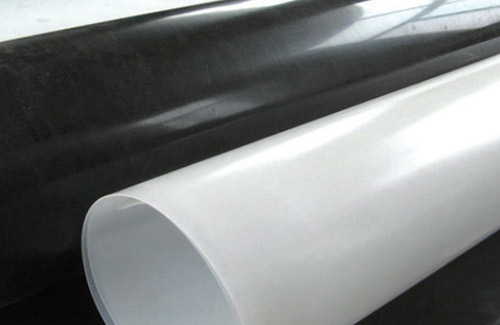

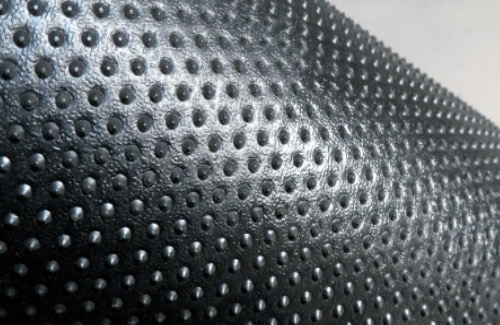

Our company has more than 10 production lines, such as advanced automatic wide geomembrane production line, geomembrane rough spraying unit, non-woven equipment production line, composite membrane production line, bentonite waterproof blanket production line, polymer self-adhesive waterproof membrane production line, etc., all indicators meet the technical standards of the United States and the European Union.

According to your engineering needs, we provide pre-sale, in-sale and after-sale integrated solutions such as engineering design, material customization, technical guidance, construction and welding.

Welcome to contact us and visit our company.

FAQ

FAQ

1. who are we?

We are based in Shandong, China, start from 2016,sell to Domestic Market(90.00%),Southeast Asia(5.00%),South America(3.00%),Eastern Europe(00.00%),Africa(00.00%). There are total about 51-100 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Geomembrane,Geotextile,GCL Liner,3D Composite Drainage Geonet,Composite Geomembrane

4. why should you buy from us not from other suppliers?

shandong yibo yangguang engineering materials co., ltd is with more than 20 years in producing geomembrane, geotextile, compsite geomembrane, gcl l iner, etc. we sincerely hope cooperate with you and hope that you can visit our factory to talk more.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF;

Accepted Payment Currency:USD;

Accepted Payment Type: null;

Language Spoken:English,Chinese

We welcome the opportunity to work with you on your next infrastructure project. Send us a message, and our team will get back to you promptly.

FAQ

FAQ