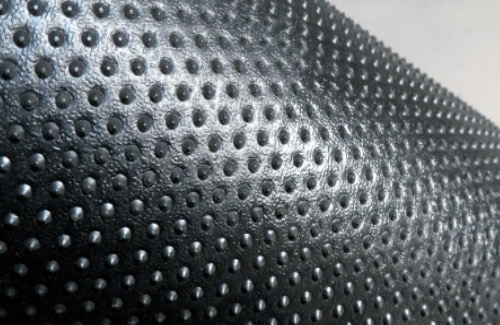

Product introduction:The spinning (single / double side) textured surface HDPE geomembrane adopts secondary molding

process. Based on the HDPE smooth surface production process, the secondary spraying of the "textured

spinning" is used by the “Geomembrane Spray Roughing Unit” to spray the rough material on the smooth surface.

Product specification:thickness 0.5 ~ 3.0mm, width 4 ~ 8m, length according to engineering design and customer requirements.

Product features: in addition to columnar rough surface high-density polyethylene geomembrane, in addition to excellent chemical

stability, mechanical properties, environmental stress crack resistance, dimensional stability, and heat aging resistance,

it also has a beautiful appearance, large friction coefficient, and resistance to the good sliding function is very suitable

for slope laying or steep slopes and vertical anti-seepage, which facilitates the second laying of geotextiles, and at

the same time can enhance the resistance to deformation of the membrane.

Scope of application:Municipal environmental protection engineering, waste landfill treatment project, sewage treatment project,

metallurgical and petrochemical industry anti-seepage, anti-corrosion project, petrochemical anti-seepage and

anti-pollution project, tailings treatment, red mud pile anti-seepage and anti-pollution project, power plant ash

dam anti-seepage, anti-fouling and anticorrosion projects.

Product implementation standard:GB/T17643-2011 ( GH- 2T1 type、GH- 2T2 type、Geosynthetics―Polyethylene geomembrane

CJ/T234-2006 High density polyethylene geomembrane for landfills

GRI-GM 13 American Present Standard

Hot Products

Customized Composite Drainage Geonet Manufacturer

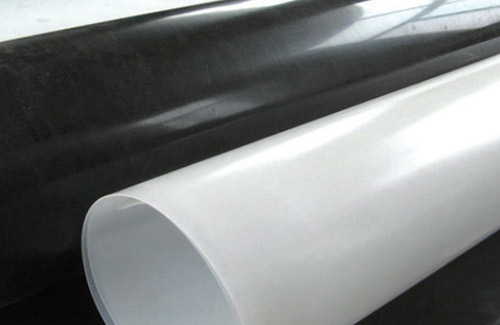

Low Density Polyethylene Geomembrane

Environmental Protection textured Surface High-density Polyethylene column point Geomembrane

Environmental Used Textured Surface High-density Polyethylene Geomembrane

Environmental Protection Used Smooth Surface High-density Polyethylene Geomembrane